MAINLINE CCTV

By far, the video camera is most pivotal to our business. It is the introduction to our customers’ problems, and the results of the video dictate which options are available to complete the project.

Mainline cameras routinely inspect 6” to 20” diameter pipe and can traverse up to 1200’ in a single pass. Cameras are remotely controlled, transmitting audio and video data to the on-board computer.

The mainline cameras are standardly equipped with pan and tilt capability and a zoom feature allowing a more detailed inspection of the pipe. For challenging conditions, MSI maintains an array of specialty cameras to achieve the desired results.

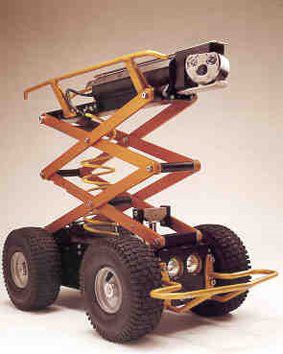

STORM DRAIN and CULVERT CCTV

Storm drain tractors are used to video large pipes exceeding 22” in diameter. The tractor can be remotely steered to avoid obstacles and the over-sized tires assist in crawling over debris. By activating the scissor lift, the technician can adjust the camera vertically for better visibility.

MINI CAMS & MIGHTY MINI

Mini cameras are useful alternatives to mainline cameras when access points to the pipe are limited in size. They are capable of entering pipe through smaller openings and can negotiate bends that mainline cameras cannot. From a 1 ½” to 8” diameter pipe, the mini cameras can traverse up to 400’ of pipe. These small cameras are particularly useful when used in conjunction with location equipment to pinpoint areas in need of repair.

LATERAL LAUNCH CCTV INSPECTION

The contributions of defective sewer laterals affecting infiltration and sewer maintenance issues up to this point have been difficult to quantify. To address this uncertainty, MSI utilizes the capabilities of RS Technical Services Gen2 Mainline & Lateral System.

A picture-in-picture format allows visuals from both cameras simultaneously allowing the operator to investigate both the sewer main and the sewer laterals. The inspection is conducted from the manhole causing no more inconvenience to area residents than a standard video inspection.

The launch system camera can be remotely rotated by the operator for easy insertion into the lateral with a range of up to 100’. Assessments regarding the condition of the sewer lateral are compliant with NASSCO LACP.

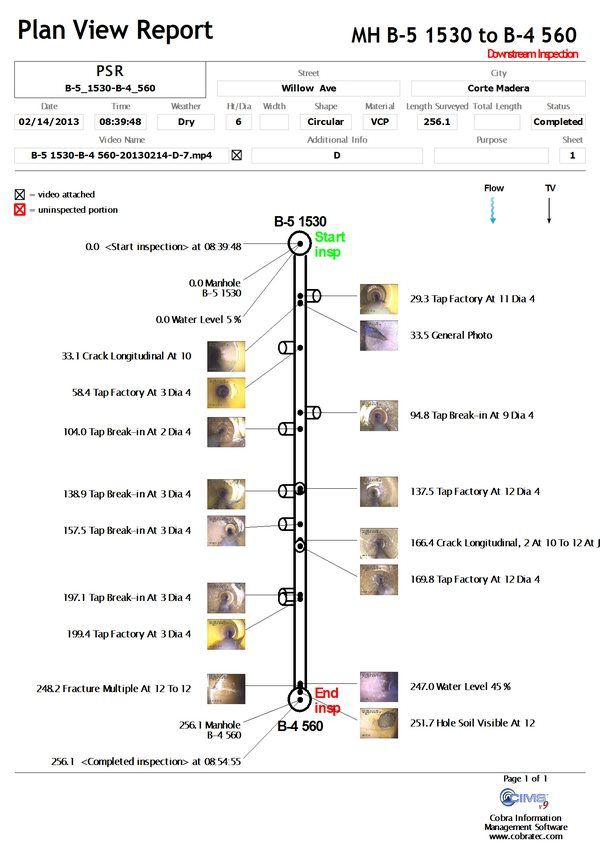

DATA COLLECTION SOFTWARE

The results of the pipeline video inspection are produced in a digital format submitted on DVD’s or on a removable drive per customer request. Written reports accompany the video for each pipe segment inspected. Any faults detected in the pipe are noted along with the footage location. All camera technicians are PACP certified in pipeline assessment in accordance with NASSCO standards.